Easton

Yi HUANG

Linkedin / Google Scholar / CV

I am a Ph.D. candidate in the Mechanical and Aerospace Engineering Department at Rutgers University-New Brunswick.

I am a member of the Robotics, Automation, and Mechatronics (RAM) Lab, and my supervisor is Prof. Jingang Yi.

I completed my M.Sc degree at the National University of Singapore supervised by

Prof. Andrew Y. C. Nee and Prof. ONG Soh Khim.

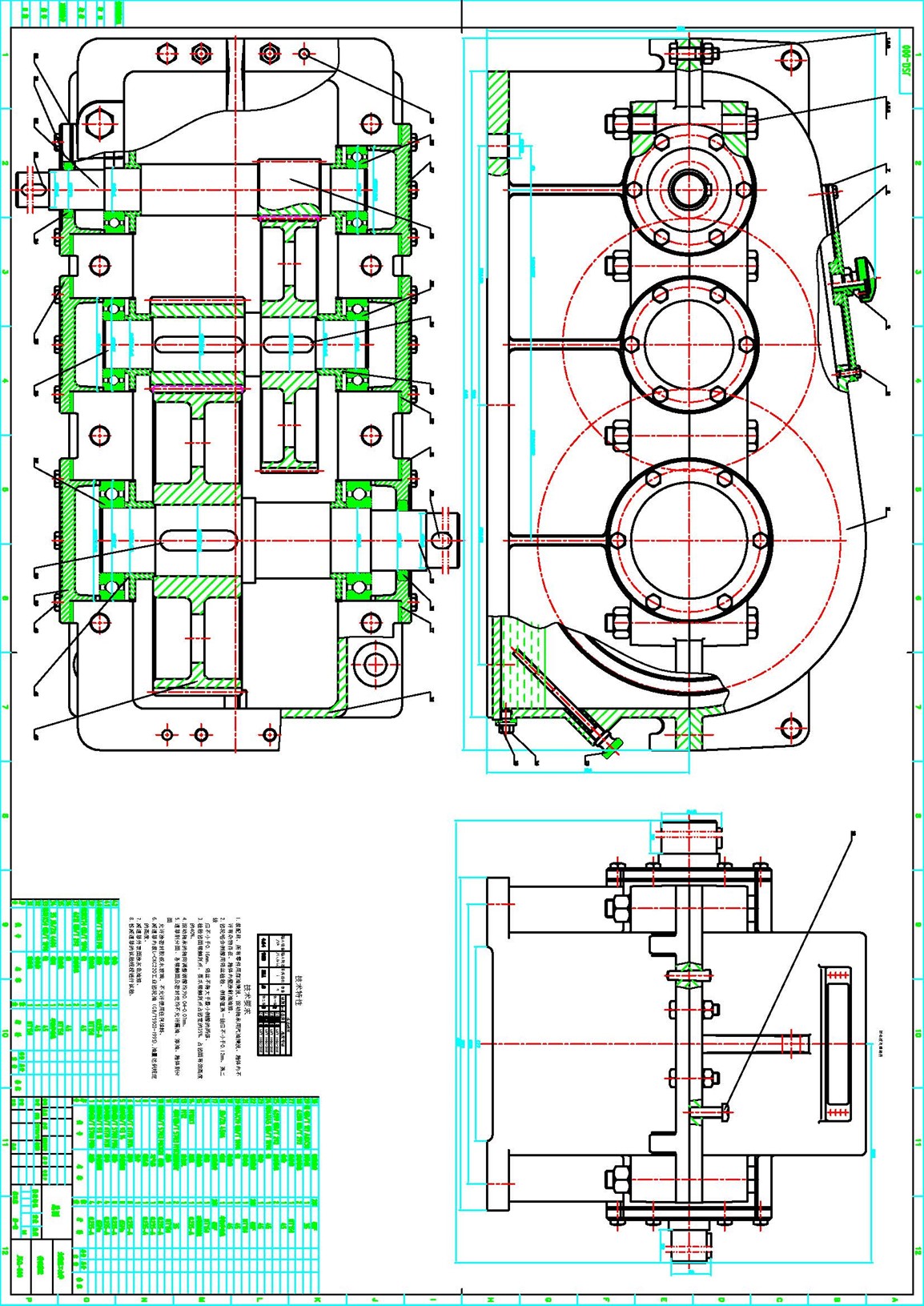

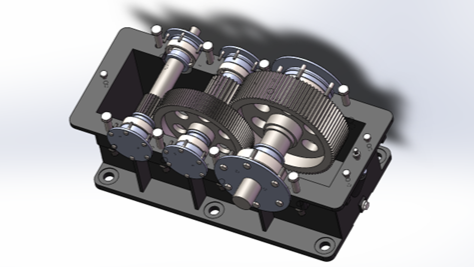

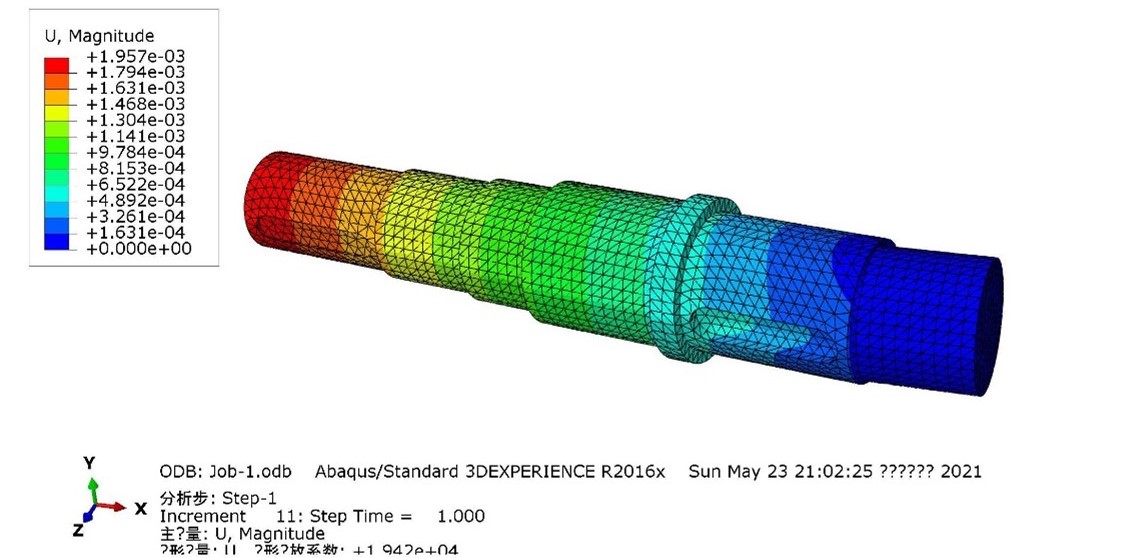

I received my B.Eng. degree at Dalian University of Technology.

My final year project was supervised by Prof. LU Wen Feng at NUSRI.

Estimation of the region of attraction (RoA) of dynamic systems is a challenging task due to complex nonlinear behaviors. Analytical approaches require accurate dynamic models and are commonly conservative. In this paper, we present a data-efficient, machine learning-based RoA estimation strategy for an unknown dynamic system with multiple attractors. Our approach constructs and maps the dynamics onto the Riemannian manifold with potential function. The initial RoA is estimated based on regions with low potential values and high gradient magnitudes. To refine the RoA boundaries, further sampling is directed towards regions adjacent to the initial estimation, ensuring an adaptive and efficient data collection process. A Morse graph-based RoA expansion strategy is finally applied to identify the boundaries of RoA. We demonstrate the proposed RoA estimation method by using both simulation and experimental results for inverted pendulums with various controllers. Comparison with other RoA estimation methods is also presented to demonstrate the superior data efficiency and accuracy of the proposed approach.

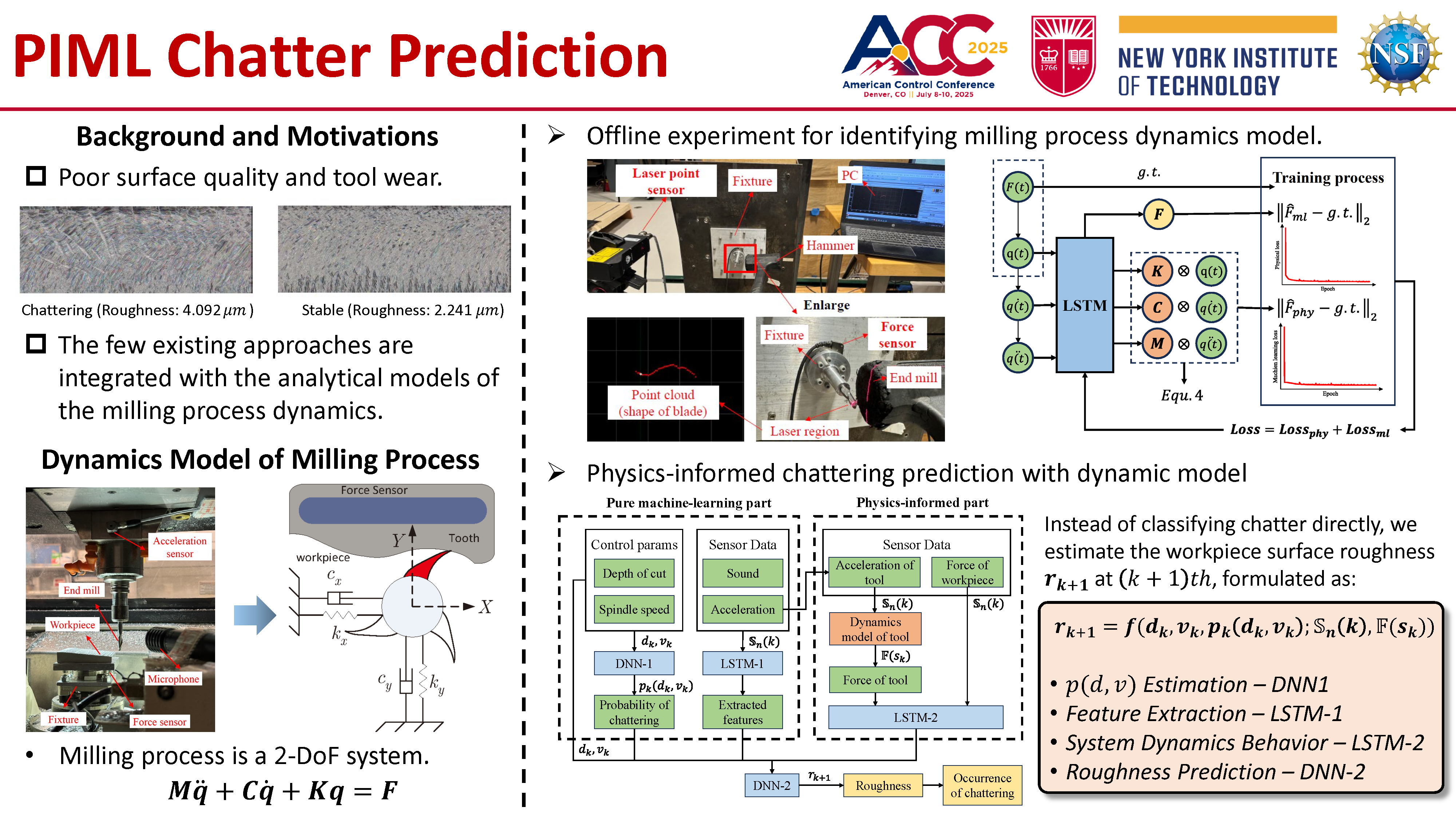

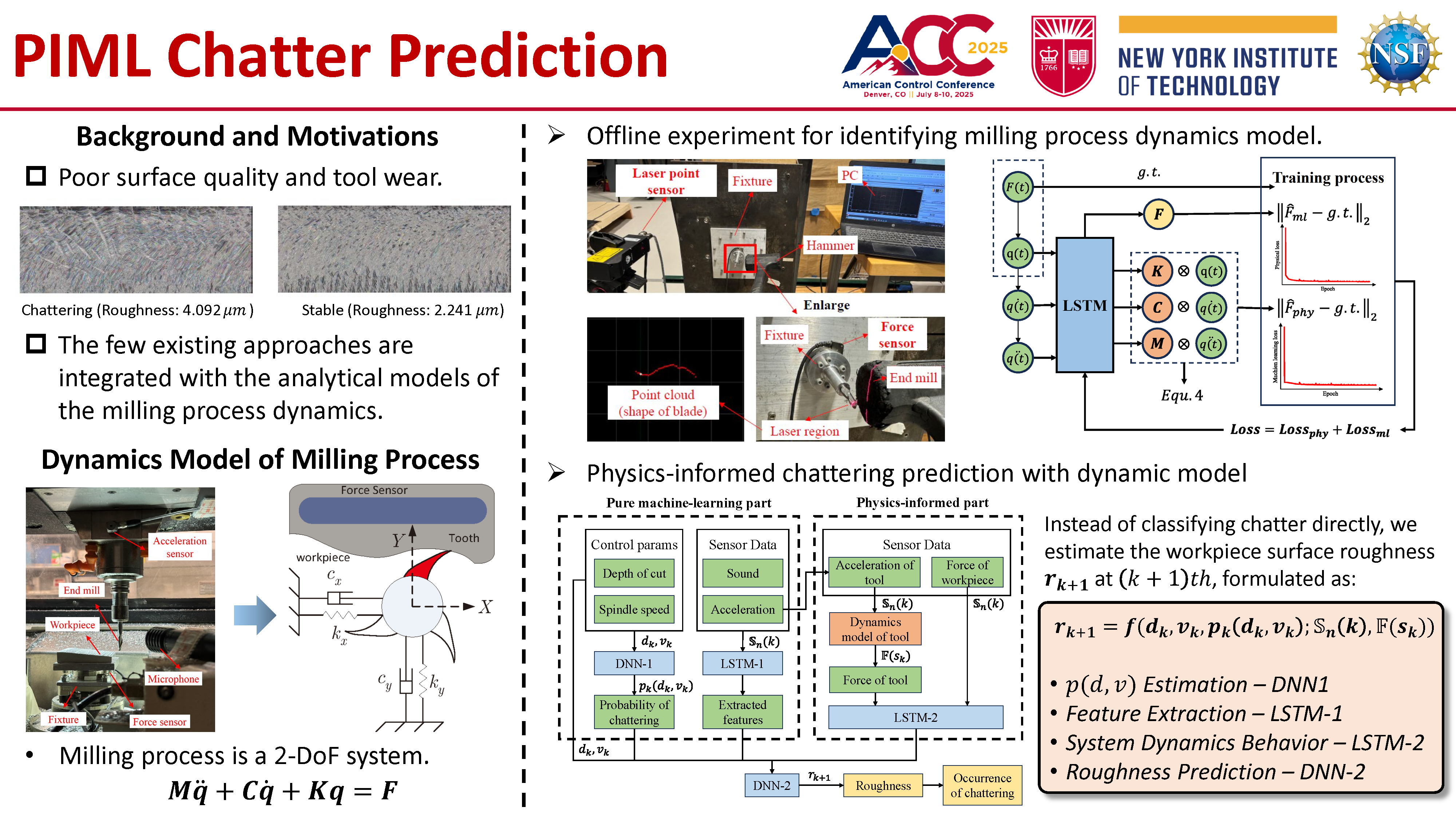

Chattering is a self-excited vibration phenomenon that results in poor surface quality of the workpiece in machining process. Analytical prediction of chattering initiation requires exact knowledge of milling process dynamics. Machine learning (ML) classification tries to effectively incorporate measurement data for real-time chattering prediction and suppression control. This paper proposes a physics-informed ML-based approach by integrating a deep neural network model for off-line dynamic parameter identification and a long short-term memory model for online real-time chattering prediction. In the offline phase, we extract critical dynamics parameters that inform the subsequent online chattering prediction. Experiments are conducted to validate and demonstrate the chattering prediction design. The comparison with another ML-based chattering prediction method is also presented to confirm the superior performance and reliability of the proposed approach.

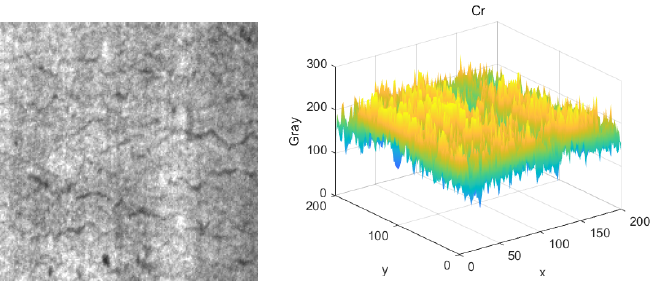

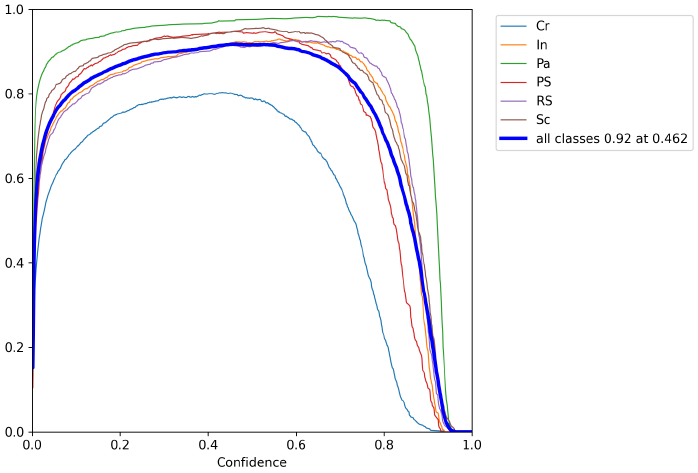

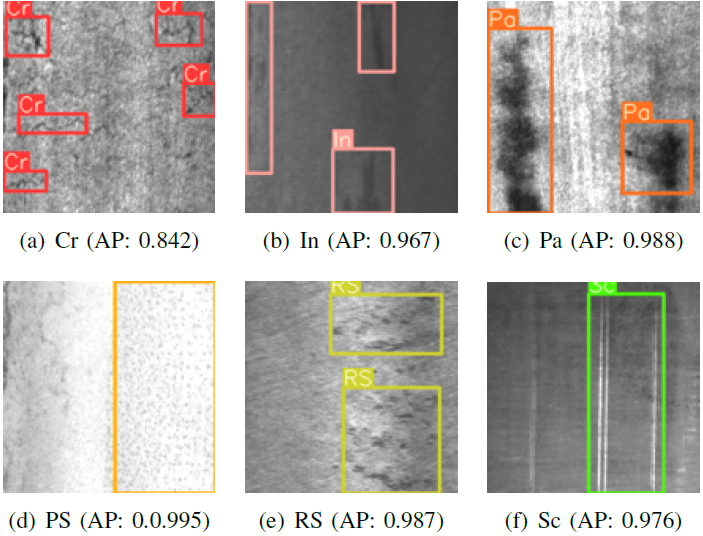

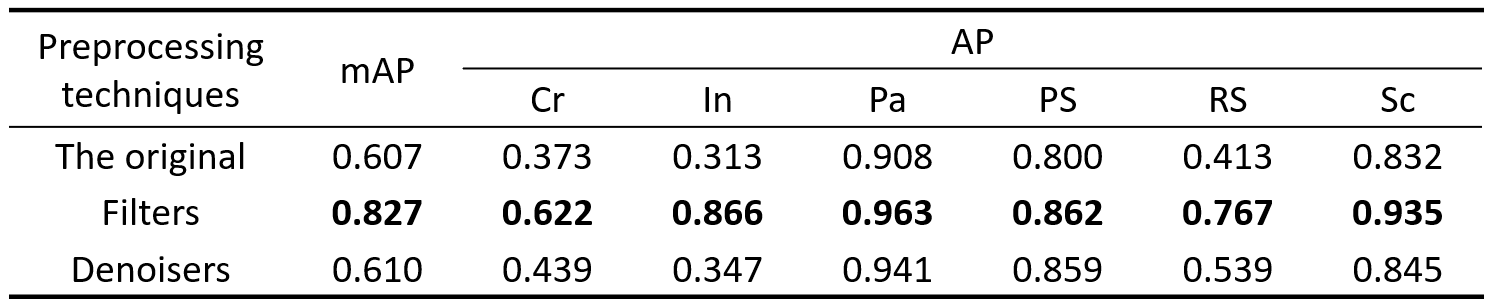

With the high demand for steel surface quality, the requirement for defect-free steel surfaces is growing. Integration of machine vision with deep learning performs impressively. Our work aims to look into efficient surface defects detection algorithms, and to attempt to improve defect detection performance. This paper reports the use of YOLOv5 for steel surface defect detection and achieving 95.9% mean average precision (mAP). Moreover, we have improved detection accuracy by preprocessing the database with filters and denoisers based on CNNs. After applying denoisers and filters, apparent improvement can be seen in each type of defect after using either one of the techniques. For example, after applying denoisers and filters, the detection average precision (AP) of Rolled-in Scale defects increased by 12.6% and 35.4%, respectively. In this paper, the efficiency of machine vision based on deep learning, and the effectiveness of preprocessing in improving accuracy for steel surface defect detection is demonstrated.

Keywords: machine vision, defect detection, deep learning, denoising.

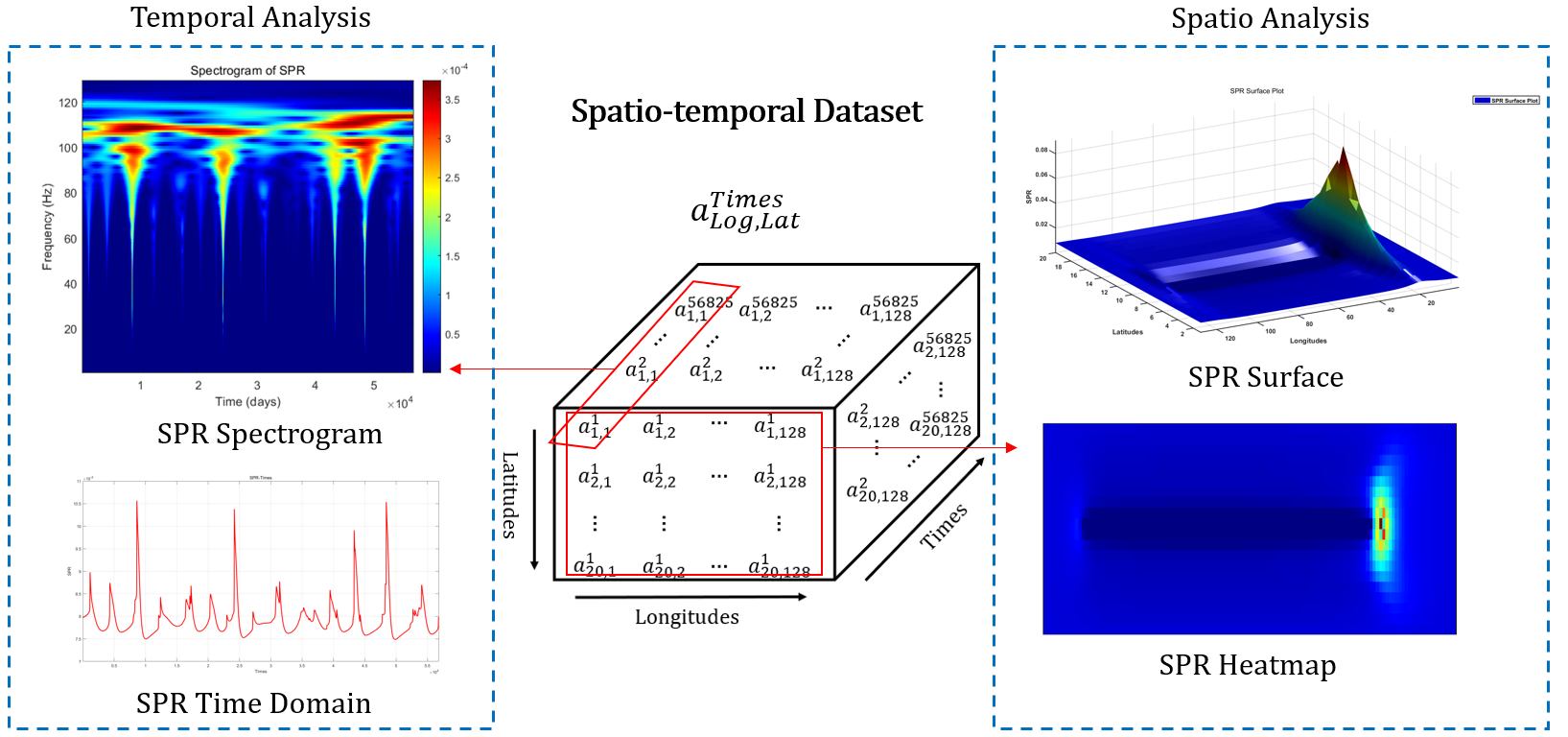

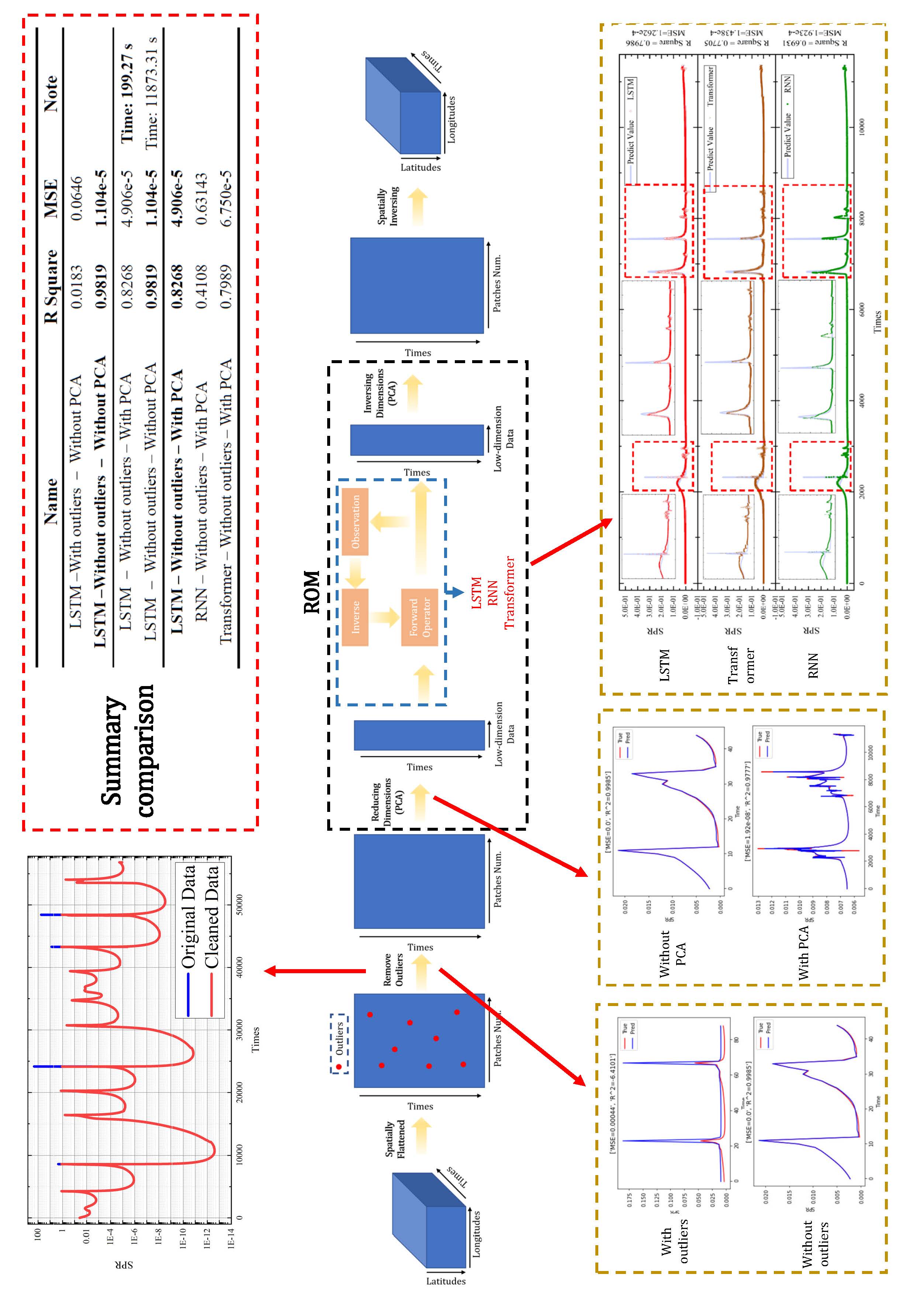

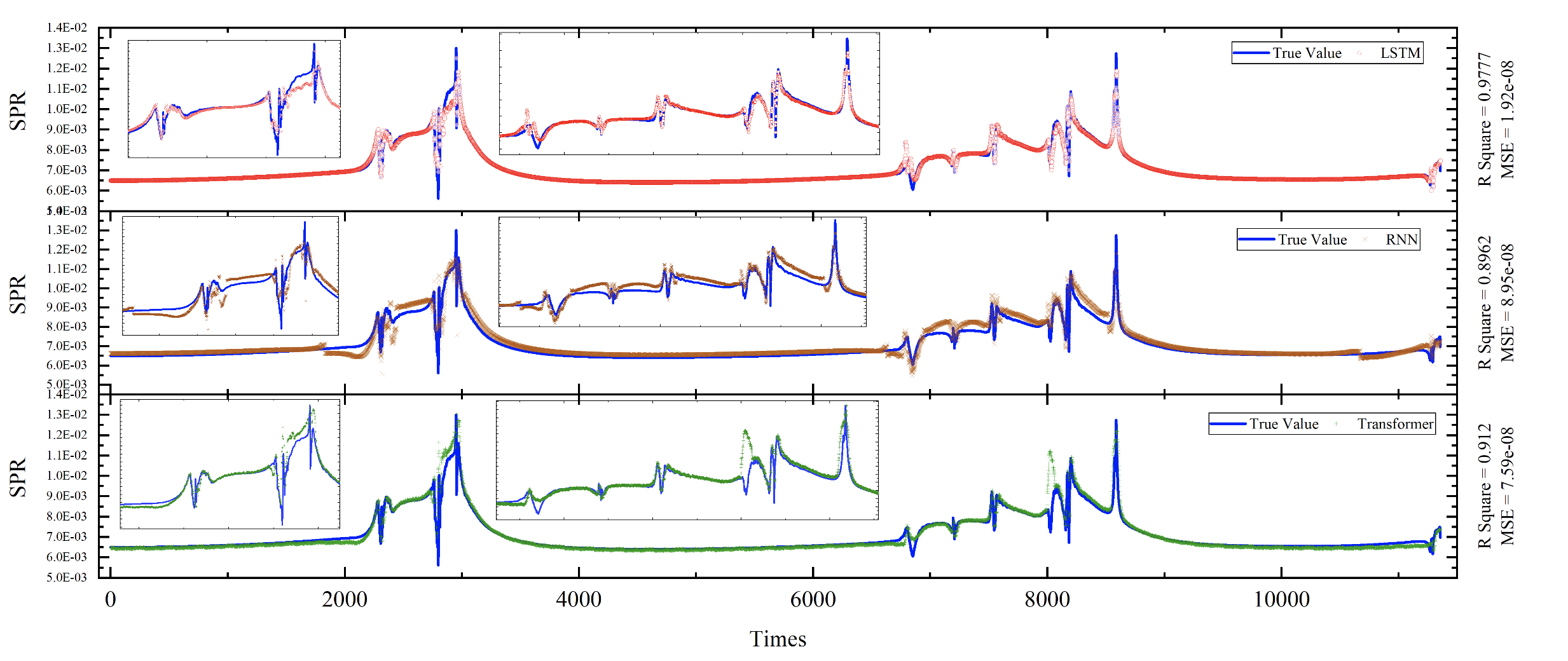

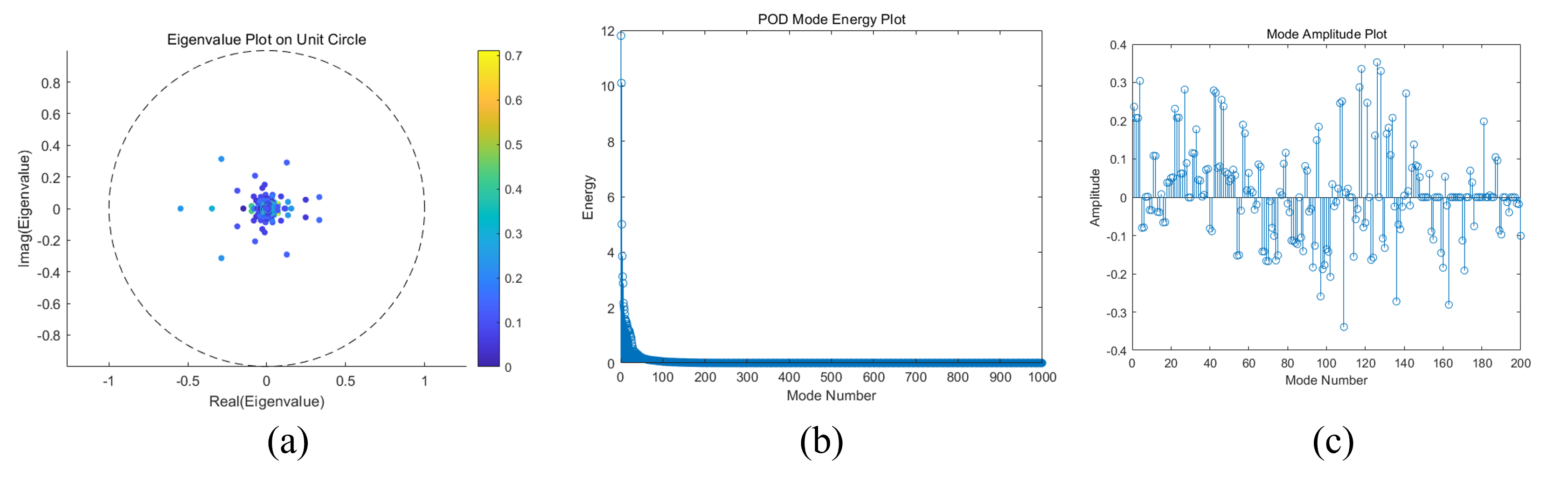

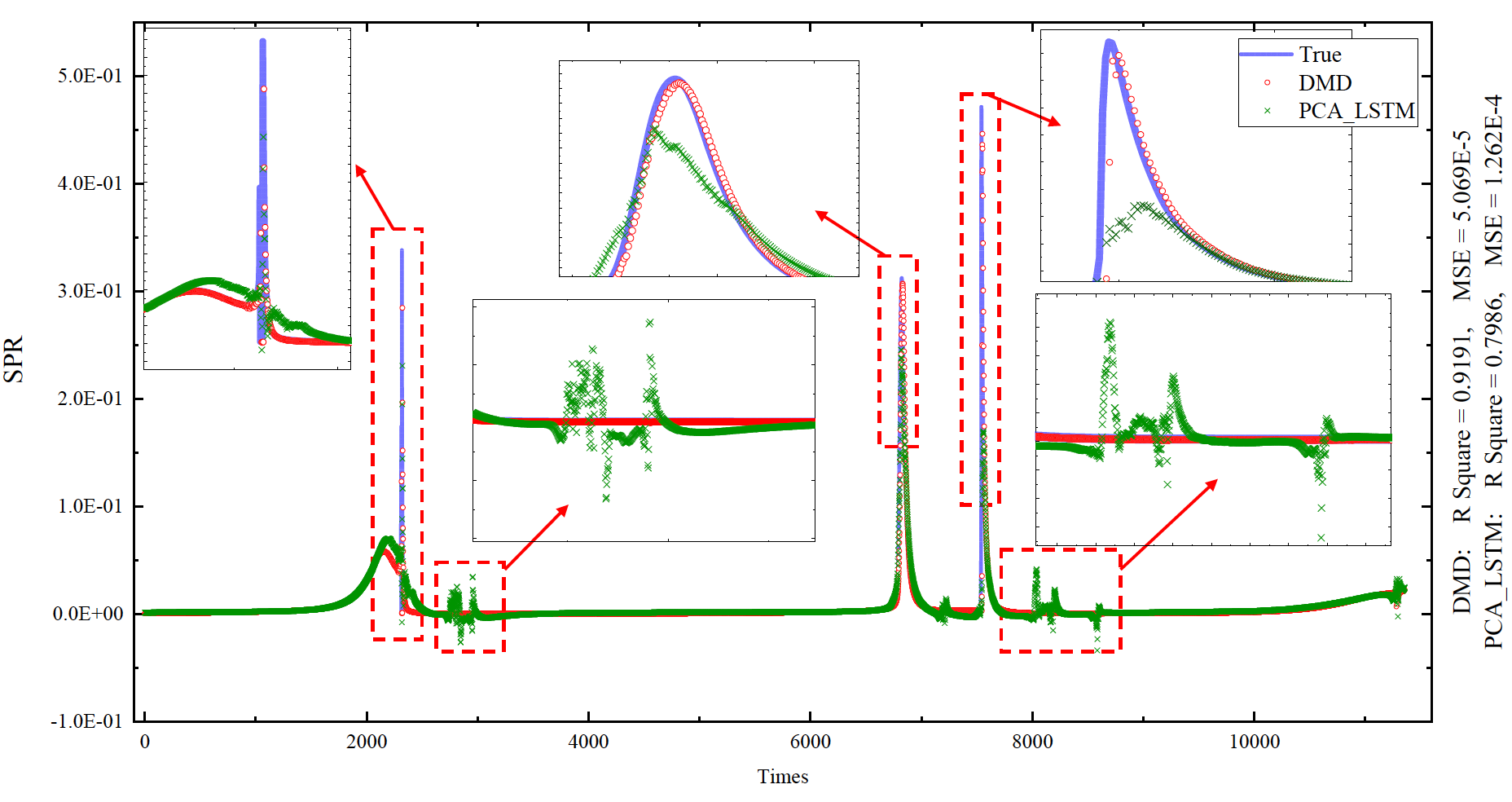

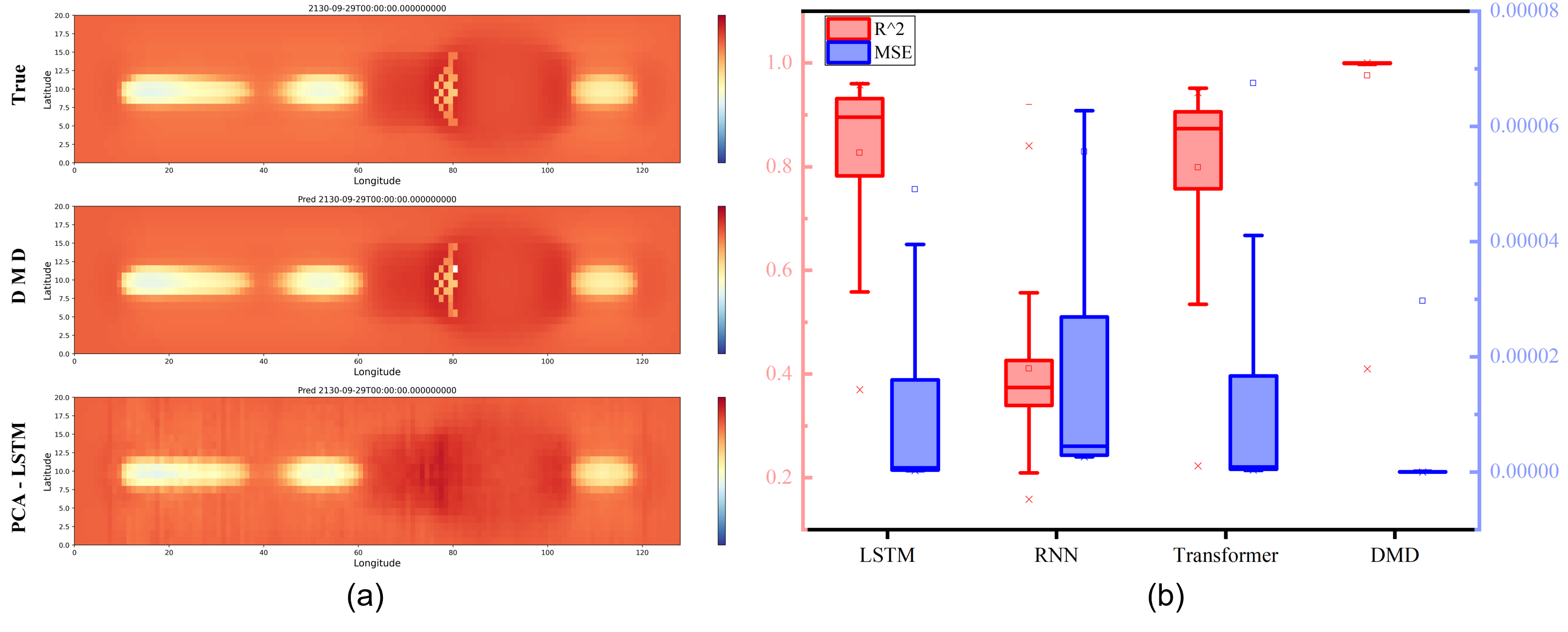

Spatio-temporal (ST) earthquakes prediction is significant for prevention of damages. In this report, there is a dynamic high-dimensional dataset of SPR sampling from two-dimensional space. This report proposes a flow which can be used in general dynamic ST system. The flow includes dataset preprocessing based on analysis, two techniques to reduce the order of this system, and four prediction techniques. First, after visulizing the dataset and analyzing the dataset in space, time, and frequency aspects, the outliers, which are regarded as noise, are removed. Meanwhile, through system eigenvalue asnd energy of modes, system predictability is judged. Then, in order to reduce system complexity, order reduction techniques are applied. One of the reduction techniques is based on the PCA technique. Another is dynamic mode decomposition (DMD) with Koopman which is widely applied in the dynamic system. Inversing of reduced order system is also important, this report compares the reduction techniques from accuracy of prediction and inversing accuracy. Finally, the main-stream black box time series models, including LSTM, RNN, and Transformer, are applied. Those black box models are compared with white box technique which is dynamic mode decomposition (DMD) with Koopman.

Keywords: spatio-temporal prediction, reduced-order model, dynamic mode decomposition.

My girl@Dongguan

The smoker@Dalian

Lost@Langkawi

Link@Kuala Lumpur